AW Bell was established in 1952 by Alan Bell as a patternmaking business. Building on these humble beginnings, AW Bell has transformed to now being a specialist in casting solutions, be it in investment casting, sand casting or prototyping. We even offer our own patented process for casting aluminium.

We have refined our knowledge and developed supporting services such as production machining, assembly, NDT testing. We are truly a one stop shop for all your casting needs.

Today, we are proud to produce complex metal products with high mechanical properties for aerospace, defence, biomedical and other industries with demanding standards. Offering a complete service from design to assembly, we pride ourselves on being able to deliver tailored solutions.

We are able to deliver on this due to our continued commitment to innovation, our people and our facilities.

Unable to easily find quality equipment to improve efficiencies in the aftercast process, in 1984 A.W. Bell Machinery was born through the development and manufacture of its first in house grinder. Today, A.W. Bell Machinery continues to design and manufacture equipment specific for foundry operations such as cut off saws, waterblasts and grinders to foundries all over the world. To learn more about our A.W. Bell Machinery division visit their website, www.bellmachinery.com

In 2011 in conjunction with the CSIRO we developed the Aluminium Billet Equipment (ABETM) casting process which allows for complex cast geometries to be produced in investment casting without overdesign. This process is now a preferred method for aerospace complex parts as it overcame weight issues usually associated in this sector.

Other collaboration examples include research and development programs with Australian Submarine Corporation to develop a customer specific compact graphite iron material to extend the life and serviceability of engine components. AW Bell also supported Marand Precision Engineering in the development of machined castings in a wide range of materials for the F-135 service trailer.

As a specialist we need to continuously invest in our people, in their knowledge and skills to further support our customers and our industry. AW Bell are proud to be involved with the Victorian Government on a workforce training innovation program that works to not only promote foundry manufacturing as a viable career path but also deliver the appropriate course to gain qualifications that is specific to foundry manufacturing.

Each year we welcome new apprentices and interns to our organisation and support their qualifications through relevant experience. They are our future and we are committed to supporting the next generation. This includes international interns. Since 2016, AW Bell homes interns from Pittsburgh State University for 6 month periods.

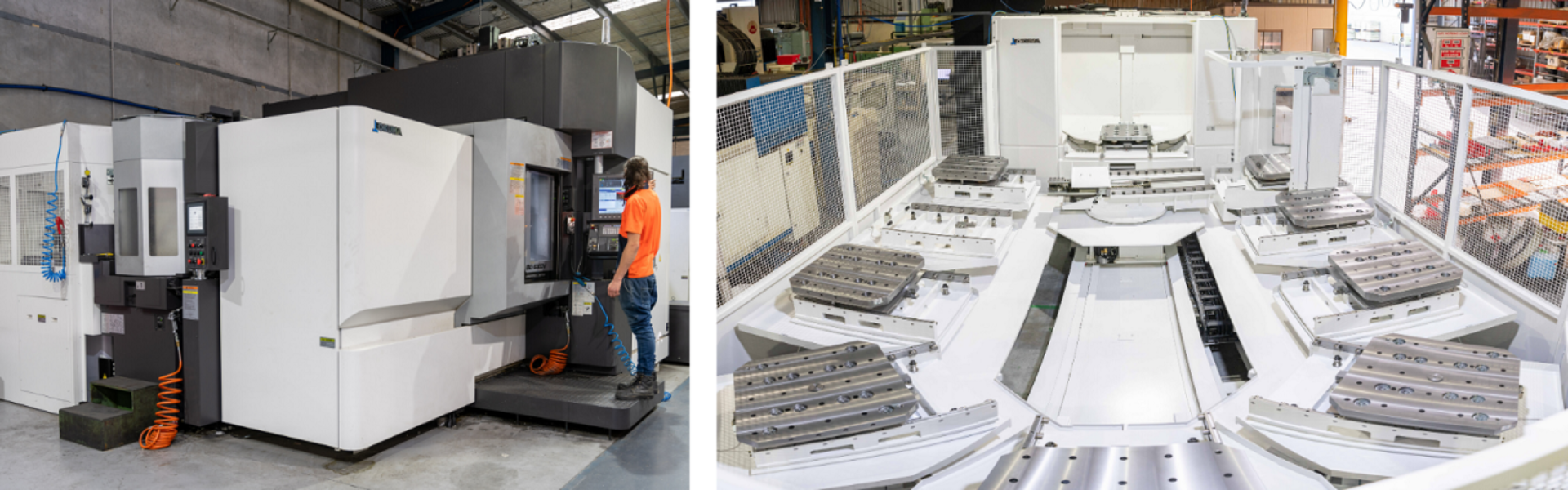

Our facility is equipped to use a range of manufacturing techniques including investment casting, sand casting, CNC machining and additive manufacturing to produce high quality, critical-duty products to specifications every time.

To enable us to deliver on the stringent and high quality castings our customers seek, we have invested on equipment and technology. This includes robotic casting processes, X-ray technology, computer controlled heat treatment furnaces, spectographic equipment for analysing the chemical compositions of the metal alloys.

The following attributes are what sets us apart and why our current customers appreciate doing business with us.

Vertical integration

From technical assistance during the design phase of a new product, through casting, non-destructive testing, machining, assembly and surface finishing AW Bell offers all your casting solutions under one roof. This reduces risk and cost by only needing one supplier to work with.

Delivery and Lead Time

With lead times significantly shorter than our US & EU competitors, AW Bell is highly reactive to customers changing needs, ramping up or reducing production as required.

Customer Service

AW Bell prides itself on the through-life cycle approach to casting solutions. Sales > Design & Development > FAI > Production > Sustainment. We respond within 24 hours through our dedicated sales and product management teams and have the flexibility to support our customer’s needs as they evolve.

Technical Capability

With world renowned materials and casting experts in our team and our AS9100 quality accreditation, AW Bell is well positioned for your most challenging casting requirements.

Our commitment to quality ensures that the parts we manufacture meet your specifications.

AW Bell is proud to be accredited with the following;

We currently hold entry-level Defence Security Industry Program (DISP) membership with the Australian government, and we also meet the high standards required by the International Traffic in Arms Regulations (ITAR). ITAR is a set of United States Government regulations controlling the export and import of defence-related articles and services.

If you would like to learn more about career opportunities within AW Bell please contact our HR Department via email at hr@awbell.com.au.

© AW Bell 2025