Integral to our capabilities are our equipment which include the latest Okuma multi pallet 5-axis vertical machining centres, Okuma multi pallet 4-axis horizontal machines and 3-axis vertical CNCs and lathes. These machines provide our customers with high accuracy components whether it be for one part or high volume production.

These are backed up by advanced CAM programming software to produce sophisticated machined surfaces for die faces and final component finishing. The accuracy of the machining provided is verified through inspection on our Co-ordinate Measure Machines (CMMs) in our metrology department.

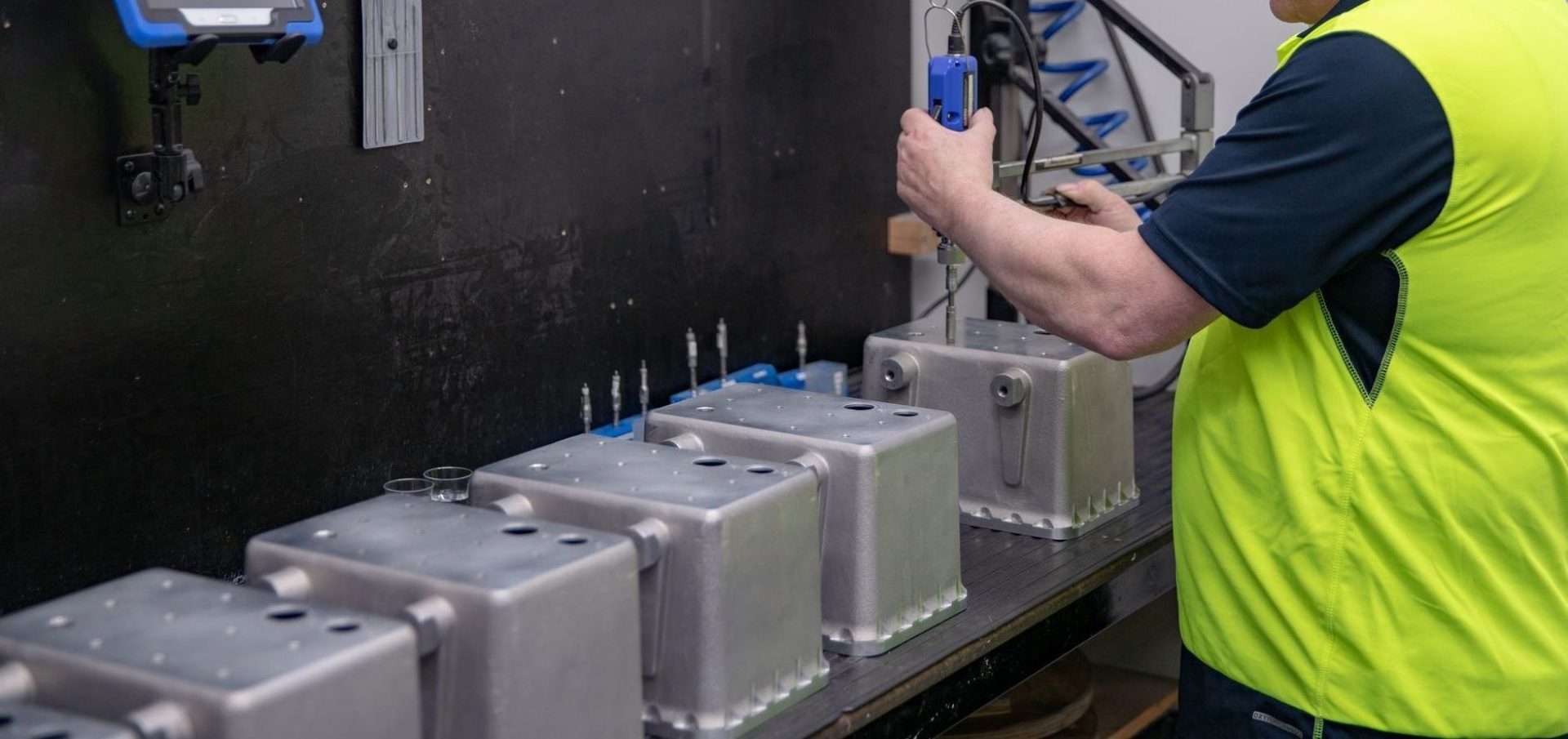

We offer assembly services such as thread inserts, pins, multiple component assembly, special adhesive applications and even painting. We also have the capabilities to test for conformance or pressure test if required.

AW Bell is truly your one stop home for all your casting, machining and assembly needs.

Our strong supply chain combined with in house painting capabilities allows for all surface treatment requirements to be met to the highest standards.

Surface treatments currently being offered include but are not limited to chromating, anodising, nickel plating, passivation, pickling, polishing, painting, carburising and case hardening.

© AW Bell 2025