The ABE casting process was developed in partnership with the CSIRO to enable the production of high strengthened aluminium castings.

ABE castings have a casting factor of 1.0 due to its superior mechanical properties. This enables product designers to design complex aluminium products that are lightweight and high in strength.

Our robotic, computer controlled casting processes enable us to consistently meet very demanding dimensional requirements and mechanical properties. Consequently, ABE castings is used for aerospace, defence and high performance automotive products.

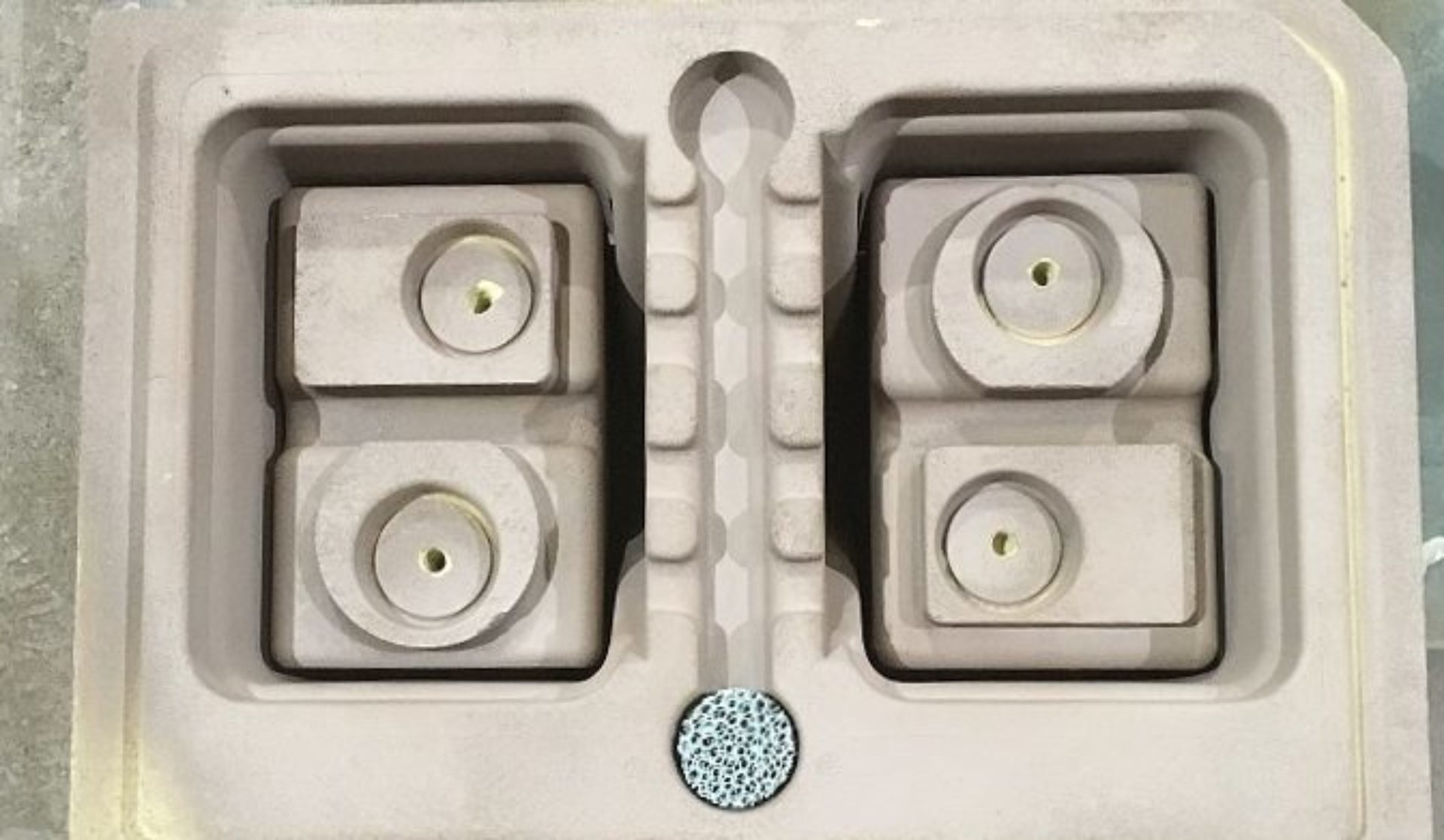

Our sand casting process is an ideal cost effective method for simple geometries or parts with enclosed shapes where coring is required.

Our vast experience with the design and manufacture of sand casting tooling allows us to produce the highest quality prototype or production sand castings in the shortest times.

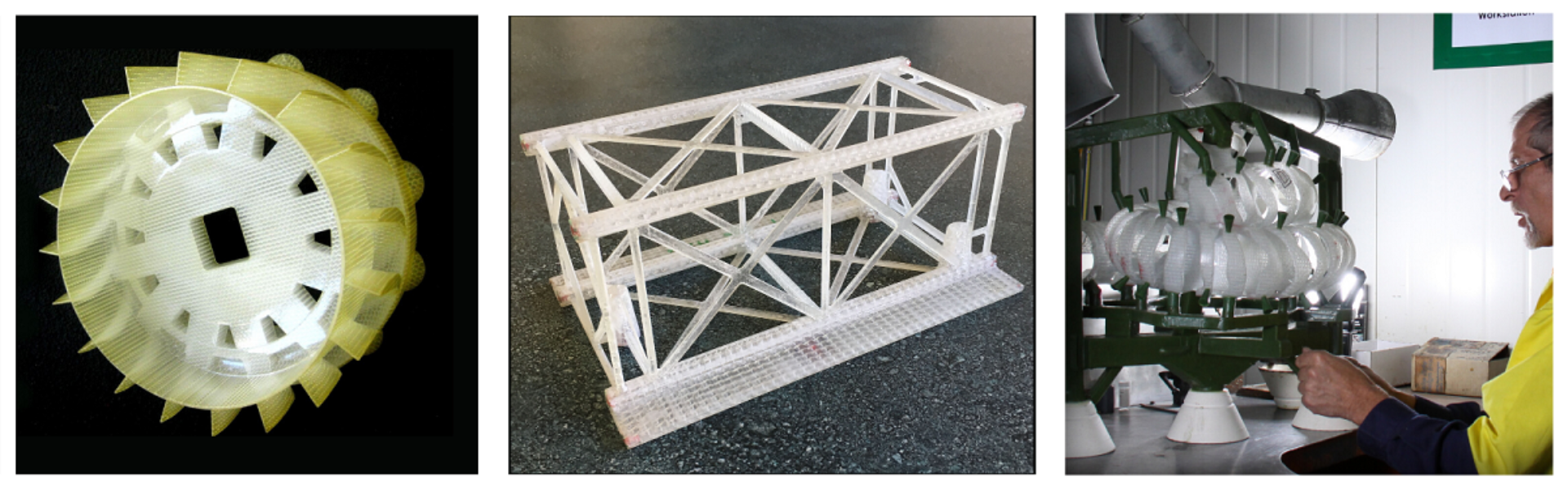

Since 2000 we have been using 3D printing technology to create metal prototype components.

This process uses CAD data to print in 3D. It removes the need for production tooling, making it a viable option compared to traditional casting processes if lead time is an issue.

3D printing is ideal for one off prototypes, research and development and small production runs. The metal components have the same mechanical properties that would be expected from parts manufactured using production tooling.

© AW Bell 2025